Opening Hour: (10.00-19.00)

Opening Hour: (10.00-19.00)

Regenerative Pumps

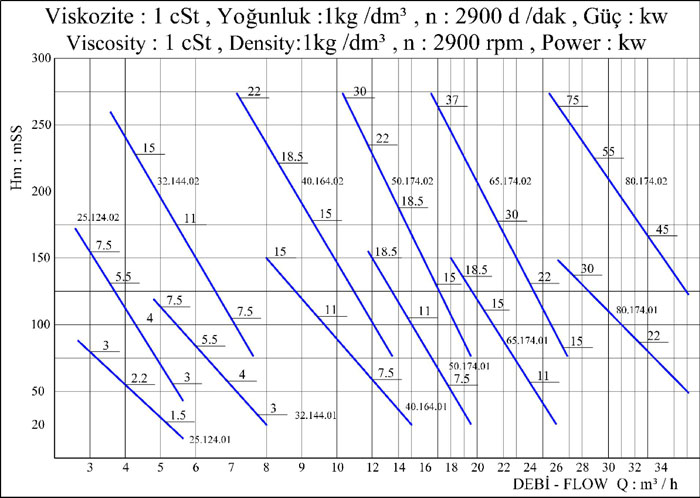

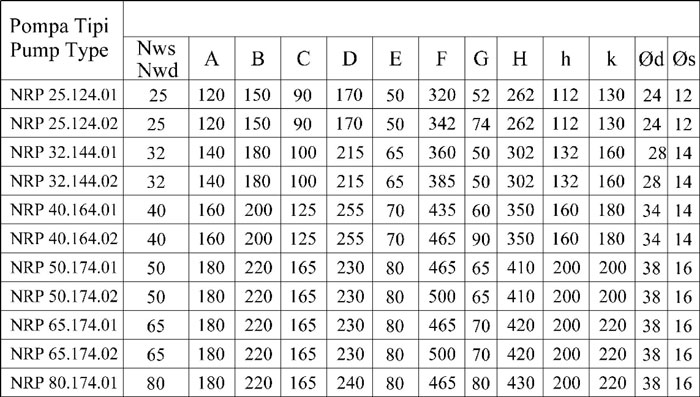

Technical Properties Performance Curves of Regenerative Pumps

Regenerative Pumps Types Sešim Tablosu ( 1450 d / dk ) Selection Chart ( 1450 rpm )

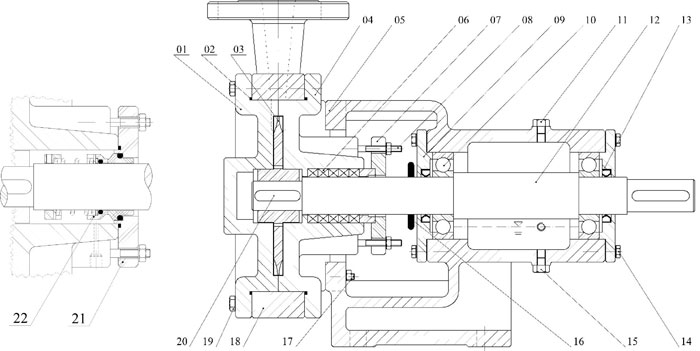

Sešim Tablosu 2900 ( d / dk ) Selection Chart 2900 rpm  Dimensions 2D and 3D Drawings Will Be Loaded to My Site Soon !   Part List

|